On a recent Friday, Ranger Jody arranged for all the staff at the park to take a Cumberland Gap Tunnel Tour. Cumberland Gap National Historical Park owns the tunnel, but leases it out to the Kentucky and Tennessee Departments of Transportation for management. We drive through the tunnel almost every day and usually twice on the days we work. I was excited about getting to see the inside workings of the tunnel.

The Cumberland Gap Tunnel Tour was absolutely awesome. I had never thought about how much work goes into managing a tunnel. There are 38 staff just at this tunnel! They are all trained in fire and ambulance rescue because they will be the first to respond if there is an accident in the tunnel.

The Cumberland Gap Tunnel was originally proposed because 25E through the gap was a very dangerous road. 25E was originally built in 1916 and modernized in the 1960’s. But the 2.3 miles through the Gap was a death trap. It was called “Massacre Mountain” by the locals and there were 8 to 10 deaths per year on this stretch of road. Locals talk about how dangerous the road was with its narrow switchbacks and speeding coal trucks.

After Cumberland Gap National Historical Park was established in 1955, the Park Service initiated discussions about a tunnel. During the next decade, studies were conducted that recommended a tunnel to improve the roadway and money to restore the scenic and historic attributes of Cumberland Gap.

In 1979, geologists examined exposed rock on the surface of the mountain and identified the various rock types. Next, a small-diameter horizontal core hole 2000-feet long, was drilled to provide even more geologic detail. In 1985, a pilot tunnel, 10-feet high, 10-feet wide and 4100-feet long was excavated. This revealed many characteristics of the mountain that would later pose challenges to the Cumberland Gap Tunnel project. Thick clay infillings, limestone formations, caves and a lake were encountered. Numerous underground streams were a major challenge as well.

Although Congress initially appropriated money for the project in 1979, the battle to improve the deadly U.S. Route 25E crossing, dragged on for two decades. Eventually funding was included in a national highway budget. Kentucky and Tennessee each committed money to operating and maintaining the finished tunnels.

On June 21, 1991, construction began on the project with the blasting of the northbound tunnel. On July 9, 1992, the two sides of the tunnel met in precise alignment in the center. The project was completed 1,947 days after the initial blast at a cost of $280 million. On October 18, 1996, a ceremony involving officials from Virginia, Kentucky and Tennessee celebrated the opening of the Cumberland Gap Tunnel.

The tunnels, each carrying two-lanes of traffic, were bored through 4100-feet of solid rock. At the tallest point, the tunnels are 30-feet high. Cross passages, located every 300-feet, connect the two tunnels and are equipped with fire extinguishers and phones for emergency use. Since the mountain releases approximately 450 gallons of water every minute, thick PVC liner around the tunnels ensures that the bores stay dry. Variable message board signs are located in the Cumberland Gap vicinity to warn drivers of impending hazardous traffic and weather conditions or to direct traffic flow.

On our tour we got to see the Control Room. Operators monitor screens connected to the eight cameras located in and around each tunnel. The operators only work two hours before they take a long break, so they don’t get fatigued and stop watching the monitors. The operators can change the message boards in the tunnels and at the entrances to the tunnels.

One of the first things Tom and I noticed about the Cumberland Gap Tunnel is that haz-mat trucks are escorted through and traffic is stopped. We get plenty of warning when traffic is stopped and it is only stopped for a minute or two while the trucks move through. When we asked why this tunnel has an escort, they told us there were two reasons. 1. There isn’t another way over the mountain for hazardous materials. The closest roads over the mountain are close to 60 miles in each direction. 2. There is a National Park site over the tunnel and it would be bad if it blew up.

Our tour group met a lot of the staff working in the tunnel, although we were asked to leave the control room operator alone so he could concentrate on the monitors. We saw the offices, and stood at the windows on the observation hall over the tunnel. In addition, we toured the garage where the ambulances, fire engines, and tow trucks are parked. We stood on the walkway in one of the tunnels and watched the cars whiz past. Our last stop was the machine and utility room. It is incredible the amount of electricity needed to run the tunnel.

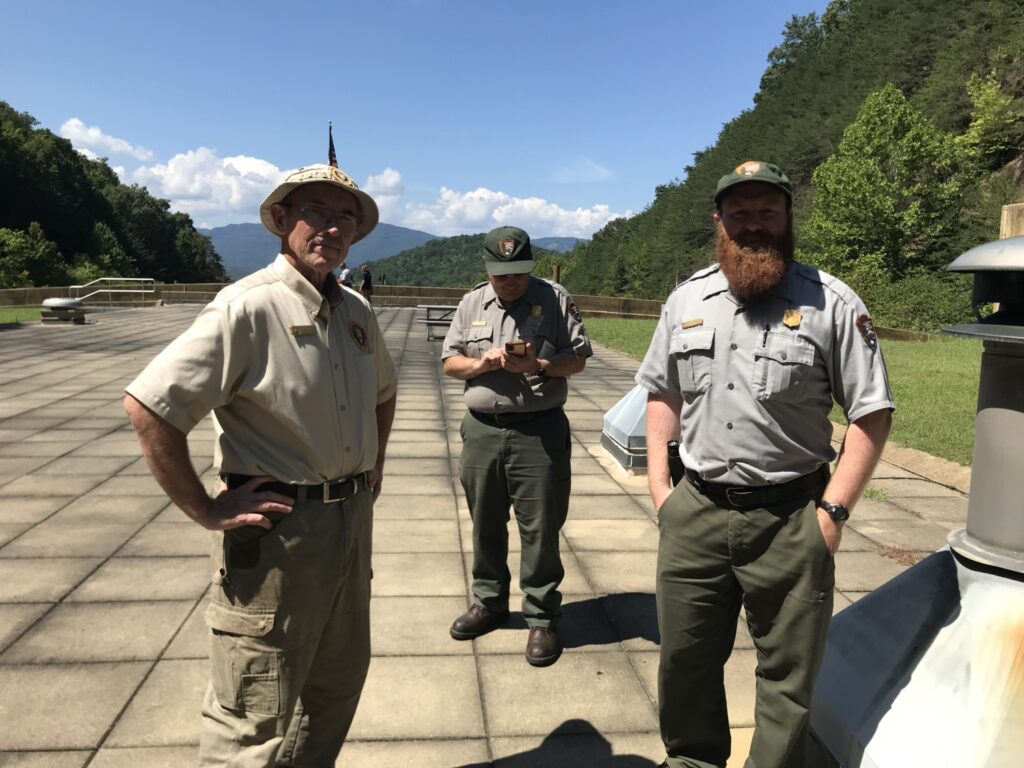

Our favorite part of the tunnel tour was climbing up out of the tunnel to a patio on the top of the tunnel. From the patio we got a great view of the cars coming into and leaving Kentucky. Although we were surrounded by the park, it felt like we were cut off from it in our own beautiful area.

The Cumberland Gap Tunnel Tour was very interesting and informative. We get questions at the park every day about the tunnel and now we can answer them with first-hand knowledge. Thanks to our boss for arranging the tour and to the Tunnel Manager, Robert Morrison, for giving us the tour. It was one of the highlights of the summer.