After getting so many stamps in one day, Tom and I slowed down and just got two the next day. The first stamp was for Springfield Armory National Historic Site in Massachusetts. This was an important stop for Tom, who deals with historic weapons all the time in our work in the national parks. We were afraid we would have to skip it. We planned on taking two days to get all the stamps in Boston, and wouldn’t get to Springfield Armory until Monday. Unfortunately Springfield Armory is closed on Mondays and Tuesdays. Because we got all the Boston stamps in one day, we were able to make it to Springfield Armory on Sunday.

After the American Revolution, President George Washington was convinced that the United States needed an armory to provide guns for its army. With the support of Congress, two armories were established in 1794. One in Harper’s Ferry, which was in Virginia at the time. The second was located in Springfield, Massachusetts. Springfield Armory provided arms for the northern states. Harper’s Ferry provided them for the southern states.

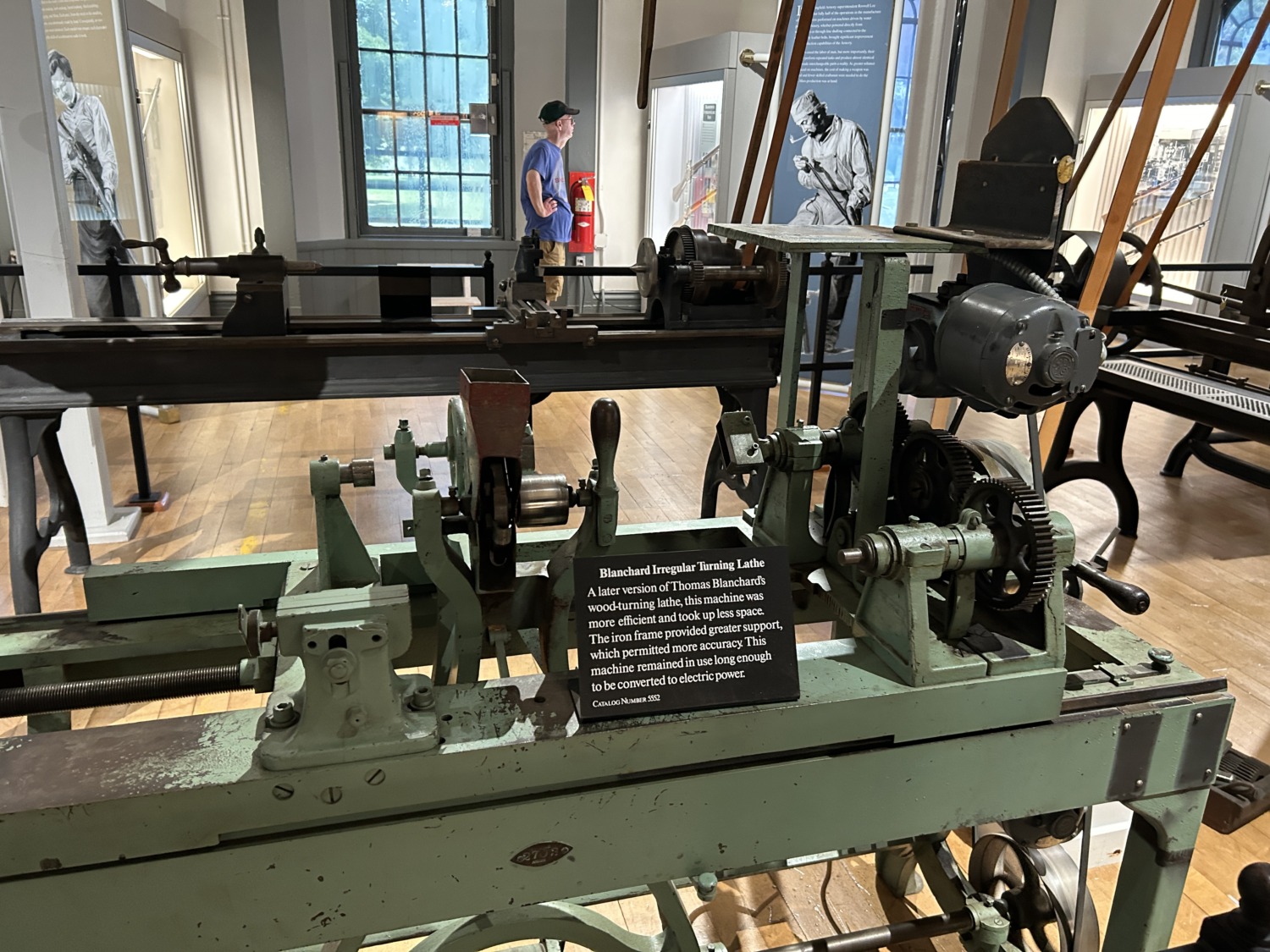

From its location on a hill, the Springfield Armory carried out the manufacturing, storage, repair, testing, and development functions assigned by the United States Army. In doing so it stimulated technological innovation. The Blanchard lathe was developed by armory employee Thomas Blanchard in 1819. It was the first machine to allow an unskilled worker to turn out identical irregular shapes quickly and easily. He had earlier developed a lathe for making uniform gun barrels.

Recurring fires at the Armory led to all the buildings becoming brick in the 1800’s. During the Civil War, the Springfield Armory produced over 1,000,000 Springfield Model 1861 rifles. This production of uniform guns gave the North an advantage in the war. The South had difficulty providing enough ammunition because the caliber of their guns varied so much.

The Springfield Armory also contributed to improved business management techniques. Colonel Roswell Lee, hired as superintendent in 1815, brought centralized authority and cost accounting for payroll, time, and materials to a manufacturing environment. These are all business practices still used today. In addition, the assembly line, mass production of parts, and division of labor were all adopted at Springfield before they were used in other places.

In 1865 there were thousands of muzzleloaders left over from the Civil War. Master Armorer Erskine Allin introduced the “Allin Conversion,” which incorporated breech-loading into the now-obsolete muzzleloaders, thereby extending their service life. In 1891 the Armory became the army’s main laboratory for the development and testing of new small arms.

During World War I and World War II, most of the weapons used by American servicemen had been developed and manufactured by the Springfield Armory. Over one million M1903 rifles, 25,000 M1911 pistols, and thousands of M1917 Enfield Rifles were manufactured for WW I. In 1924, a Springfield employee John Garand developed a design for a semi-automatic rifle. This was the famous M1, or “Garand rifle” as it came to be known. The Springfield Armory produced over 4.5 million of them for use in World War II.

The Springfield Armory was closed in 1968 and the manufacture of weapons shifted to private companies. The main building and 20 acres was given to the NPS for historic preservation. The remaining buildings became the Springfield Technical Community College. STCC is the only is the only community technical college in Massachusetts. It is free for all Massachusetts residents. The college continues the Armory’s technological tradition.

When Tom and I arrived at Springfield Armory National Historic Site, we had to drive through the STCC campus to get to the museum. Although the building has three stories, only the first story is open to visitors. We talked to the rangers and they pointed out the layout of the museum. The movie and gift shop are in the middle.

One side of the museum explains the manufacture of the guns, especially the early history. There were a variety of machines in the middle of the area and a volunteer who was talking about their use. One of the machines was an original Blanchard lathe that the volunteer turned on to demonstrate its use.

The other side of the museum had individual guns and the history of their development. I was especially interested in the one-minute videos that showed how the firing mechanisms of each different type of gun worked. The museum features the world’s largest collection of historic American firearms.

We watched the movie, then checked out both sides of the museum, taking our time with each display. A ranger was giving a talk on using a muzzleloader, but Tom and I didn’t stay for that. I got my stamp and we left the building. We walked around the grounds a little and ate a picnic lunch. Then we got back in the car to head to our next stop.