After two days of weaving class at Red Stone Glen Fiber Arts Center, we reached the culmination of class: weaving a scarf. With three days remaining in class we would choose a yarn, figure out how much we needed, warp on the yarn, weave, and finish the scarf. Let the weaving begin!

I chose a tencel yarn for my scarf. I usually weave with historic yarns (wool, cotton, and flax/linen) so it was fun to choose something really different. Tencel is a cellulose fiber that comes from wood and feels very smooth and silky. It has a beautiful drape but also a crisp texture, somewhere between linen and silk. I chose a variegated (multi-colored) yarn in fall colors for my weft. Then I paired it with some orange and brown tencel from the odds and ends bin at Red Stone Glen. I decided to alternate 1″ stripes of orange and brown on the warp.

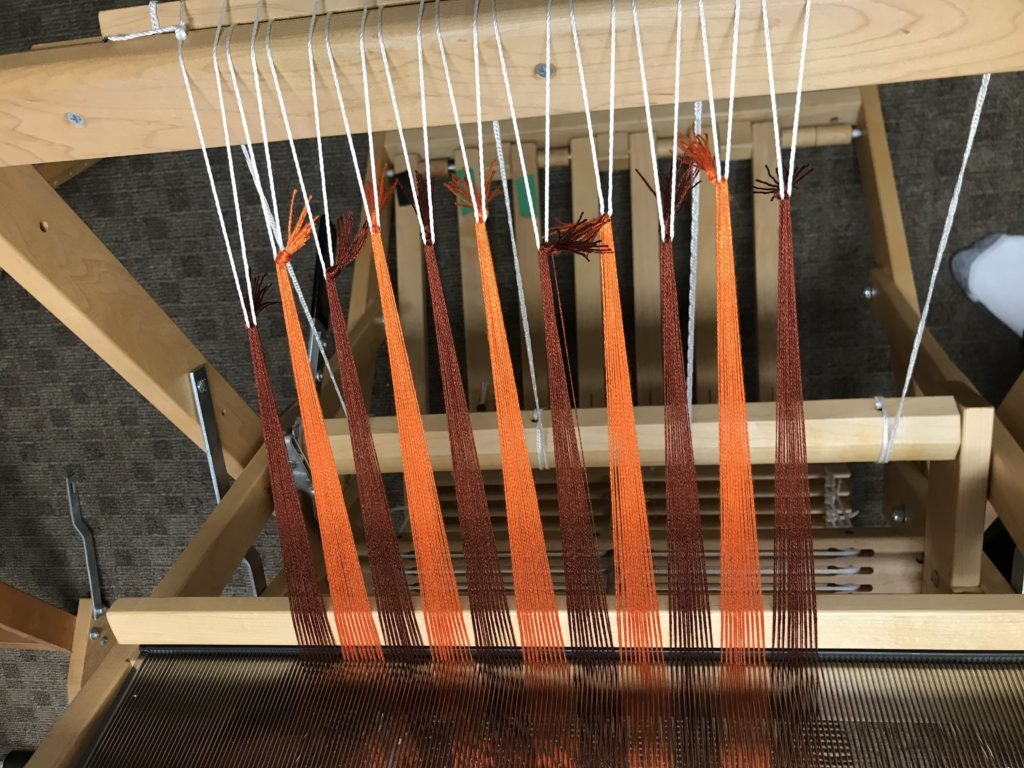

After using math to figure out how much I needed, I started warping the 220 strings on the warping board. I did 120 strings of brown and 100 strings of orange. The scarf would be 20 strings per inch and 11 inches wide. Seeing the stripes side by side made me realize they were the Cleveland Browns colors. Well, I am a fan!

Tom Knisely demonstrated each step of the warping process to us before we attempted it. Unlike all the other warping I have done, I warped this loom front to back. In warping front to back you put the strings through the reed first, then through the heddles before you tie on at the back or front. Warping this way seemed much easier with less awkward reaching. Of course, it also helped that I was working on the little Wolf Pup loom. When I was finished, my tension was much more even than it usually is, which is a very good thing in weaving.

After warping the loom, we wove and wove. My scarf ended up being 93″ inches long and I got it all done in one afternoon! Weaving goes so much faster on a floor loom. We were also doing plain weave, so I didn’t have a pattern to follow. Just row after row of shuttle across, pull the beater, change the shafts. You get into a rhythm and it moves along pretty quickly. But, my shoulders and neck hurt a bit after doing it all afternoon.

The next morning we cut the scarves off the looms and talked about finishing. I did a twisted fringe with a little tool called a “fringe twister” which was fun. Then we washed them and hung them out to dry. Before class broke up later that afternoon, we all posed for a picture wearing our scarves. They all looked great!

I enjoyed my weaving class so much at Red Stone Glen that I decided to buy a loom. I ordered one of the Schacht Wolf Pup looms. It is only 38 pounds and folds up into a 18″ deep space so it will fit in our closet. The loom will arrive in early December and I am looking forward to learning more about weaving on it.