Finally I had my new Schacht Wolf Pup Loom in hand – and in the RV. Even though the dimensions sounded reasonable when we ordered it, the loom looked a lot bigger once it was in the RV and out of the box. But, before we could get it in place, I had to put it together.

The Wolf Pup is advertised as being already assembled and it mostly was. First, I had to take off the pieces that were holding it in the folded position for shipping. There were some braces and some pieces of Styrofoam around the corners. After taking off the extra pieces, I laid out all the things in the box that weren’t attached to the loom. Because the loom is manufactured in Colorado, all the instructions were in easy to understand English. I just had to put it together one step at a time.

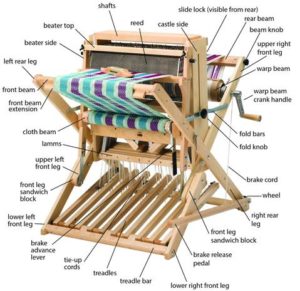

First, I figured out how to unfold the Wolf Pup loom. Then I put the heddles on the shafts. The heddles are the metal part that hold the threads and move them up and down for weaving. The loom came with 300 heddles, so 75 went on each shaft. It takes a while to get them all on the shaft in the right direction. But if you don’t have the patience to put the loom together, you are never going to have the patience to warp the loom and weave.

First, I figured out how to unfold the Wolf Pup loom. Then I put the heddles on the shafts. The heddles are the metal part that hold the threads and move them up and down for weaving. The loom came with 300 heddles, so 75 went on each shaft. It takes a while to get them all on the shaft in the right direction. But if you don’t have the patience to put the loom together, you are never going to have the patience to warp the loom and weave.

After getting all the heddles on the shafts, I attached the strings from the shafts to the treadles. The treadles are the foot levers that move the shafts up and down. With the strings I can attach any treadle, or combination of treadles, to any shaft, giving me lots of weaving options.

The last step was to attach the wheels to the loom. The wheels are supposed to make it easy to move, but they are really too small to help much. And you have to lever the loom up on the wheels in order to move it. Given the limited space in the RV, Tom and I will just lift it up and move it ourselves.

After putting the Wolf Pup together, Tom rearranged the furniture a little. He stuck my spinning wheel in the closet and stacked our storage cubbies on top of each other. Then there was room for the loom to fit in beside my recliner.

The next day I started warping the loom, and within the week I had another scarf. Not the production I hoped for before Christmas, but I have the loom and am ready to go for next year. Now that we are in Georgia, the loom is living over in living history, ready to be wheeled out for cloth-making demonstrations. I already have it warped and ready to make 10 cotton dishcloths.